Material Deep Dive: Cotton

Ubiquitous, Beloved, and More Complex Than You Think

Welcome to Fabric 101, a new series within Fabric First dedicated to building material literacy — one fiber at a time. I started this because I believe fabric education is one of the most powerful tools consumers and professionals can have in an age of misinformation, marketing buzzwords, and rising product costs. Understanding how a material behaves, and why, lets us make better choices, whether we’re designing, sourcing, or simply shopping more intentionally.

Today we’re starting with one of the most familiar fibers of all: cotton.

What It Is: Nature’s Workhorse Fiber

Cotton is one of the oldest and most widely used natural fibers in the world. It comes from the soft, fluffy fibers that grow around the seeds of the cotton plant (Gossypium), which are harvested, spun into yarn, and woven or knitted into fabric.

It’s so ingrained in daily life that it’s easy to forget: cotton is a crop, and a surprisingly technical one. While often seen as a singular material, “cotton” actually refers to a family of fibers that vary in quality depending on the variety, staple length, processing method, and construction.

That cotton tee and those heavy canvas overalls? Same fiber, totally different behavior.

What makes cotton unique is its cellulose-based composition. Unlike petroleum-based synthetics, cotton’s natural polymers give it excellent breathability and softness, but also make it more prone to wrinkling, shrinking, and wearing down if not properly finished.

The Science of Cotton: Why It Behaves the Way It Does

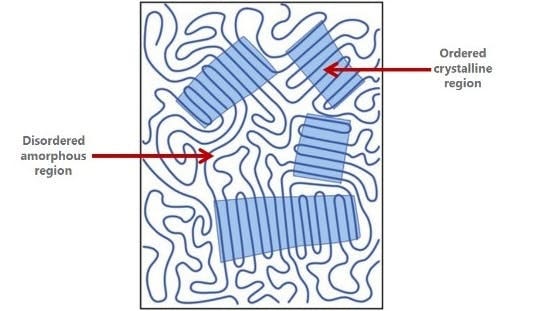

Cotton is composed almost entirely of cellulose, a carbohydrate-based polymer made up of glucose units. Cellulose forms long chains that organize into microfibrils, which further assemble into a fiber’s structural framework. These structures contain both crystalline regions (tightly packed, orderly) and amorphous regions (looser, more flexible).

Crystalline regions give cotton its strength and structure. They resist penetration by dyes and moisture.

Amorphous regions are more accessible to water, dye, and chemicals. They enable cotton’s softness, absorbency, and reactivity.

Because of this structure, cotton is naturally hydrophilic — it absorbs water readily. This makes it breathable and moisture-absorbent, but also slow to dry compared to synthetic fibers. The balance of crystalline and amorphous regions also means cotton responds dramatically to finishing treatments. Mercerization, for example, swells the fiber and increases uniformity, boosting both dye uptake and luster.

Understanding this microstructure is key to fabric performance. How a cotton fabric feels, dyes, or wears isn’t just about the fiber — it’s about the proportion of these internal structures and how they’re manipulated during processing.

How It’s Made: From Field to Fabric

Cotton production begins with harvesting the bolls from mature plants. After separating fiber from seed (ginning), the raw lint is cleaned, carded, and spun into yarn, then woven or knitted into fabric.

Quality is largely determined by staple length:

Short-staple: coarser, more prone to pilling

Long-staple: softer, smoother, more durable

The same fiber can yield very different results, think of brushed flannel versus crisp poplin. Yarn spinning, fabric structure, and finishing choices define the hand-feel and lifespan of each fabric.

What It Feels Like

Cotton’s comfort is its signature: soft, breathable, and familiar.

Hand feel: ranges from smooth to textured depending on construction

Drape: moderate; varies with weight and weave

Sheen: generally matte, though mercerization adds subtle luster

Woven cottons like poplin, voile, and twill offer structure; knits like jersey and rib provide softness and stretch without synthetics.

Where You’ll See It

Cotton shows up everywhere — from daily essentials to luxury products:

T-shirts and basics: jersey cotton for softness and breathability

Shirting: crisp poplins, oxfords, and twills from long-staple fibers

Denim: durable twill, sometimes blended for stretch

Home textiles: towels, sheets, and robes

Luxury loungewear: high-end Pima or Egyptian cotton

It’s also frequently blended with modal, polyester, elastane, or linen to enhance performance.

Pros & Cons

Pros

✅ Breathable and absorbent

✅ Naturally soft and comfortable

✅ Familiar and widely available

✅ Biodegradable when minimally finished

✅ Excellent dye and print surface

Cons

⚠️ Can shrink or wrinkle without finishing

⚠️ Prone to fading and pilling (especially short-staple)

⚠️ High water and land use in conventional farming

⚠️ Slow to dry compared to synthetics

⚠️ No inherent stretch unless blended

Why Cotton Isn’t as Simple as It Seems

Cotton is often positioned as the “natural” choice, soft, breathable, familiar. And it is all of those things. But from a sourcing and development lens, cotton is both a gift and a challenge. It’s easy to work with, but tricky to optimize without over-processing.

Fiber quality matters. A poorly sourced short-staple cotton will pill, fade, and wear out faster than a well-developed long-staple option. As a developer, knowing your supplier’s cotton source, and how it’s processed, is essential. Yarn twist, singeing, and enzyme finishes can make or break the end use.

Consumers expect cotton to be comfortable, but not all cotton delivers equally. That $5 tee is probably carded, open-end cotton with minimal processing. It’ll stretch out and pill fast. A combed, ring-spun tee with enzyme wash? Much longer life span and better experience.

From a sustainability perspective, cotton has trade-offs. Organic cotton avoids pesticides but can require more water. Better Cotton or regen cotton programs offer improvements but vary by region. And recycled cotton is growing, but challenging due to fiber length loss in processing.

Bottom line? Cotton isn’t going anywhere. But if you’re serious about fabric, you have to ask deeper questions than just “is it cotton?”

Decoding Cotton Lingo: What the Labels Actually Mean

Ever wondered what those cotton buzzwords really stand for? Here’s your quick guide:

Pima: Extra-long staple (ELS) cotton, mostly U.S. grown, softer, smoother, more durable than standard cotton.

Supima®: Trademarked 100% American Pima; verified quality and origin.

Egyptian Cotton: Another ELS variety grown in Egypt. Luxurious, but often mislabeled. Verification matters.

Organic Cotton: Grown without synthetic pesticides or fertilizers. Look for GOTS certification for credible standards.

Recycled Cotton: Made from post-industrial or post-consumer waste; often blended for strength.

Better Cotton (BCI): Large-scale initiative improving farming practices, water use, and labor conditions.

Regenerative Cotton: Focuses on soil health and biodiversity. Still developing but growing fast.

Combed vs. Carded: Combed = smoother, stronger yarns. Carded = coarser, cheaper.

Ring-Spun vs. Open-End: Ring-spun = softer and finer. Open-end = faster, rougher, budget-friendly.

Mercerized Cotton: Chemically treated for luster, strength, and better dye uptake.

U.S. Cotton Trust Protocol: Sustainability standard for U.S. cotton, tracking metrics like water use and emissions.

These distinctions aren’t just marketing, they directly affect hand-feel, longevity, and price point.

Where in the World Cotton Is Grown

Cotton is cultivated globally, but fiber quality, yield, and sustainability practices vary widely by region. Here are a few of the major cotton-producing countries and what they’re known for:

United States: Particularly Texas and California. Known for consistent quality, large-scale mechanization, and traceability programs like Supima® and the U.S. Cotton Trust Protocol.

China: One of the largest producers and consumers. Xinjiang is a key region, though sourcing here raises complex geopolitical and ethical issues.

India: Home to both conventional and organic cotton (including GOTS-certified farms). Yields and quality can vary significantly by state and infrastructure.

Brazil: A fast-growing source of high-quality, machine-harvested cotton. Invested in sustainable farming and traceability tech.

Egypt: Known for luxurious extra-long staple varieties. True Egyptian cotton is prized for softness and durability but can be difficult to verify.

Australia: High-efficiency production with advanced water management practices. Often used in premium programs and regenerative trials.

Cotton’s origin impacts everything from staple length and contamination risk to labor practices and traceability. Origin impacts everything from fiber length to labor practices.

Cotton vs. Synthetics: What’s the Real Trade-Off?

When comparing cotton and polyester, it’s important to consider not just how they feel, but how they perform in context. Cotton, as a natural cellulose fiber, is known for its softness, breathability, and comfort. It’s absorbent, making it ideal for hot climates or loungewear, but it also dries slowly and can wrinkle or shrink if not finished properly. Polyester, by contrast, is a synthetic fiber made from petroleum. It’s wrinkle-resistant, fast-drying, and highly durable. It doesn’t absorb moisture in the same way, making it better for performance wear but less breathable overall.

In terms of care, polyester is more forgiving: it holds shape and color over time and resists shrinking. Cotton may fade or pill if it’s short-staple or poorly finished, but high-quality cotton can last for years with proper care. Sustainability is also nuanced. Cotton is biodegradable and renewable, especially when sourced from organic or regenerative systems. Polyester is non-renewable but recyclable and more water-efficient in production.

Bottom line: choose cotton for comfort, polyester for performance or blends for the best of both worlds.

Good vs. Bad Cotton Examples

✅ Long-staple Pima jersey tee that resists pilling and holds color

✅ Crisp poplin shirt that maintains shape and smoothness

⚠️ Cheap, loosely knit cotton tee that stretches and pills

⚠️ Short-staple flannel that sheds and thins quickly

🧶 Curious about a specific fabric?

Drop a comment below — your question might be the next Material Deep Dive.